The Challenge of Rotor Imbalance

Rotor imbalance is a common culprit behind equipment malfunction, trailing only bearing wear in frequency. This imbalance can arise from mechanical issues, operational stresses, or temperature fluctuations.

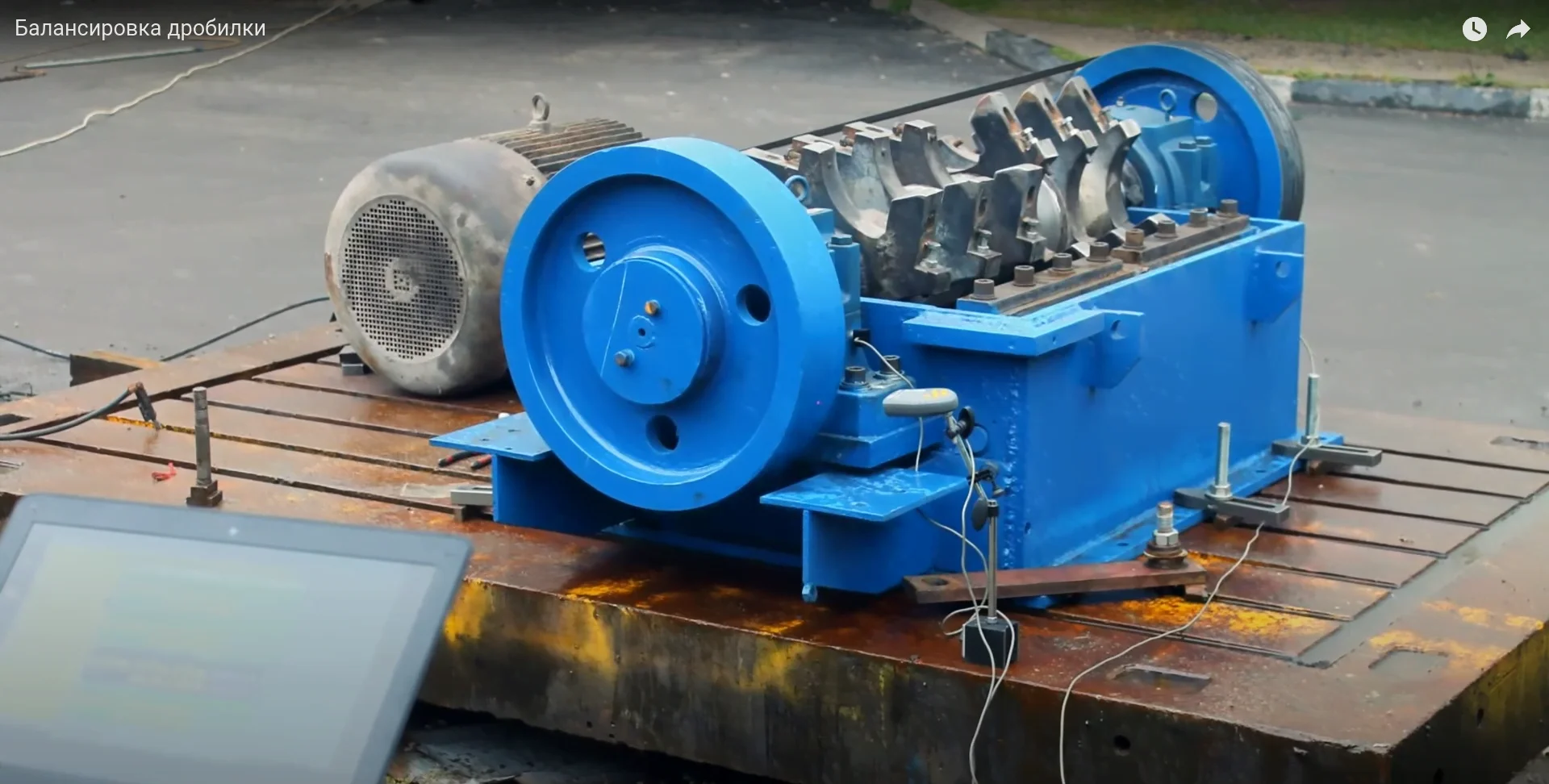

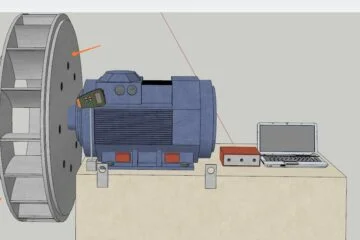

While worn bearings can only be replaced, rotor imbalance problems can often be solved without equipment disassembly through on-site balancing — one of the vibration adjustment methods for rotating machinery.

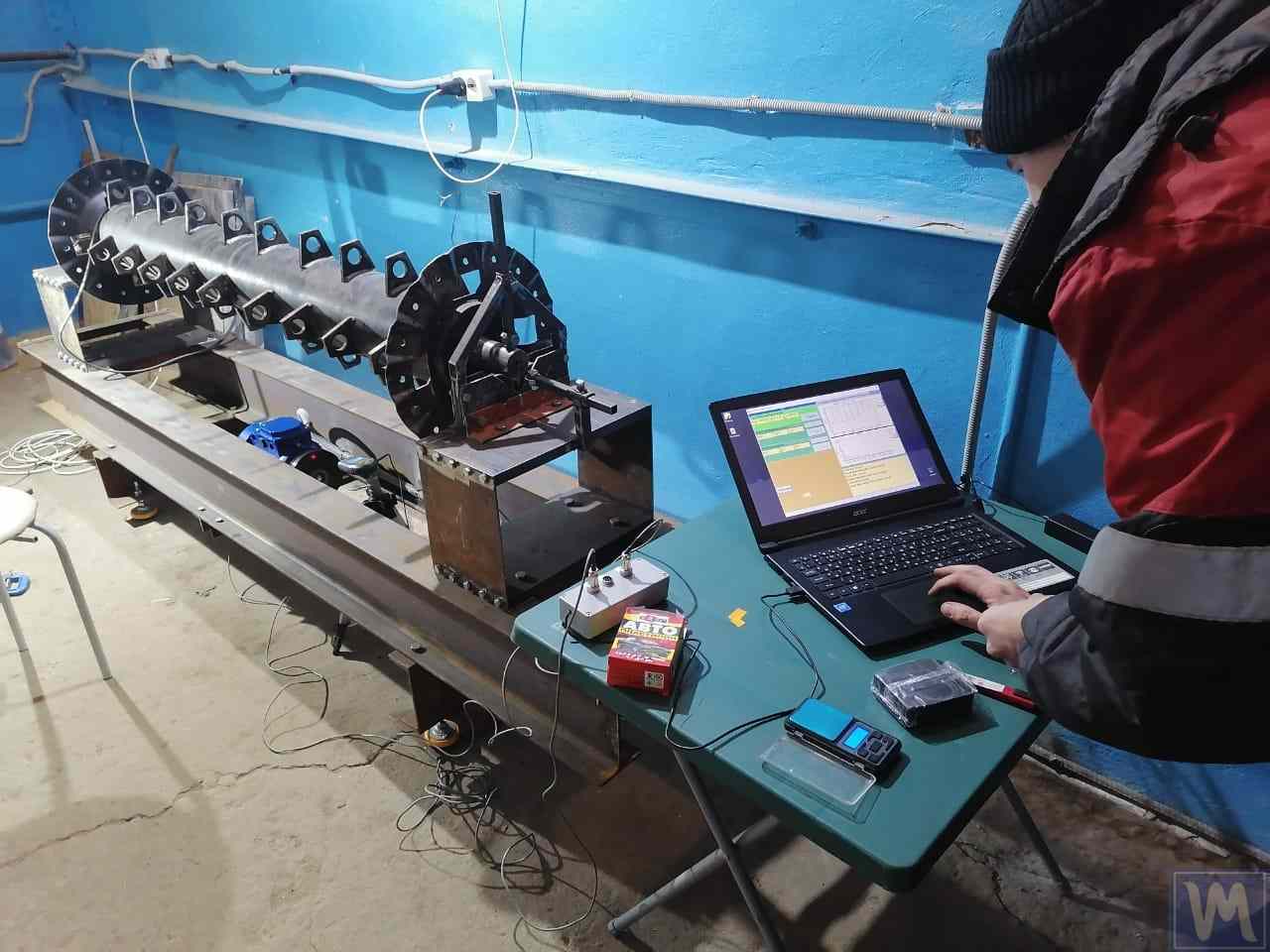

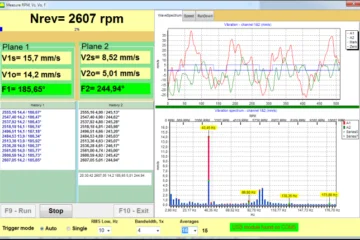

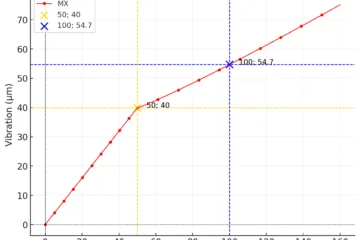

Traditionally, this process has required sophisticated, expensive vibration analyzers operated by highly trained personnel. However, Vibromera has developed the Balanset-1A to change this.